NET3001 Teaching Board

MTS2: microcontroller training system

motivation

current status

design

teaching opportunities

notes on the hardware design

Motivation

For the last few years I have been teaching a course in real time

programming. The 3 month course consists of

- assembly language programming

- C programming

- interrupts

- cooperative multitasking

The students write code on an embedded microprocessor. Previous versions

of this course use the HC12 and the MSP430.

I wanted to create a course where the students could bring the

development system home, and work with their own PC. That meant:

- open source tools

- a small portable development system

- lowest cost (including development tools)

To demonstrate the various aspects of the course, the board must have:

- a variety of easy-to-understand peripherals, with user interaction

- interrupts and real-time-clock

Current status

I have designed this

- a 6"x4" board, fits inside a VHS cassette case

- an ARM/Cortex-M3 CPU with 128kB of flash, 8kB of ram

- a programming port, which allows download and in circuit debugging

- peripherals

- LCD display, 130x130 pixels, RGB with backlight

- 12+1 button keyboard

- microphone

- beeper

- DC motor

- stepper motor

- servo motor

- 8 LED's

- one digit 7 segment display

- joystick

- temperature sensor and colocated heater

- light sensor

- thumbwheel

- two light sensors

- socket for microSD card

- 2-way radio module

- accelerometer (tilt sensor)

- UART/serial back to the host CPU

Here's a photo.

Design

CPU

I wanted the CPU to be easy to teach, and I wanted to move up to 32 bit.

That points to the ARM processors, and the Cortex in particular, which are

at a great price-point.

Debugging

The CPU needs to allow easy download and single stepping, as well as

the ability to view registers and control I/O ports. Again, the Cortex

processors do that well.

Power

Almost all the chips on the board run at 3V or 5V, so a USB cable can

provide all the power. The backlight on the LCD requires +7V, and the RS232

requires +/-7V; the MAX232 chip can generate both of these.

In order to run the servo motors, however, we need a lot more current, so

the board has a LiPo battery 150mAH which provides the surge current

required by the servo motor.

Radio

The students in the course are also learning about network protocols in

their other courses. So this board has a 2.4GHz radio transceiver. This

unit is low cost, only chews about 10mA when it's running, and has a

full packet fifo and MAC features (preamble, header and CRC assembly).

The students can either use it at this level, or introduce a link-level

protocol. The packet payload can be up to about 25 bytes, or even more

if the CRC & address fields are reduced.

Motors

There are three motors on board. The DC motor is driven by two PWM pins,

which allows us to speed it up and slow it down, and even reverse it.

The stepper motor is a 4 pin unipolar drive, so the drive sequences are

A...A...A...

.B...B...B..

..C...C...C.

...D...D...D

or

AA.....AAA......

.BBB.....BBB...

...CCC.....CCC..

.....DDD.....DDD

Both should be fairly easy to teach.

The servo motor requires 1.5msec pulses every 20msec. Teaching this will

be a challenge, and we may not get to it in the basic course.

Cost

Provisional: CDN$40 for parts. Labor will probably be me-&-free.

Many of the parts are coming from surplus houses, HongKong eBay and Digikey.

Teaching Opportunities

Some assignments which I am considering

- light up the LED's

- read the temperature

- scan the keyboard

- connect keystroke to an LED

- report keystrokes to LCD

- measure human reaction time from beep-to-keystroke,

beep-to-handclap, led-to-keystroke, led-to-handclap

- build a frequency meter to measure audio frequencies

- build an echo-locater (ultrasonic click on the beeper to

microphone delay)

- spin the motor

- send data through the radio

- build a mesh network using the radios

- simulate

- car wash

- traffic lights

- car radio

- vending machine

There are several opportunities to teach physical feedback:

- temperature sensor has a colocated heater; target: set constant temperature

- servo motor arm swings down and covers one of the light sensors:

target: move the servo for constant light flux onto sensor

- armature of the DC motor spins over the IR light sensor: target:

set the rotation speed of the motor

Hardware design notes

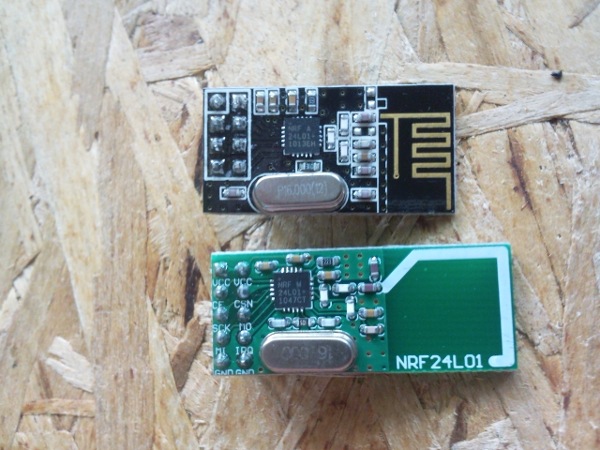

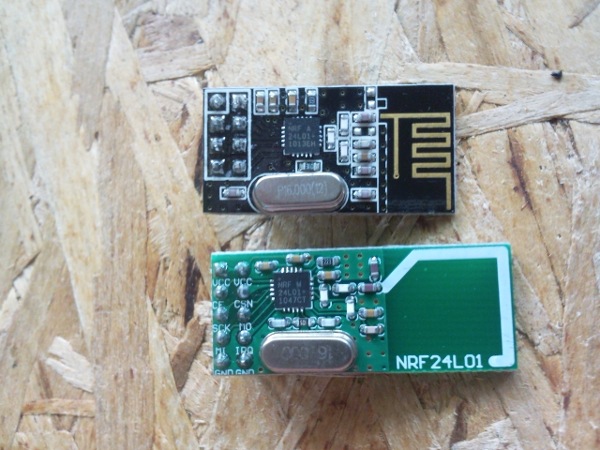

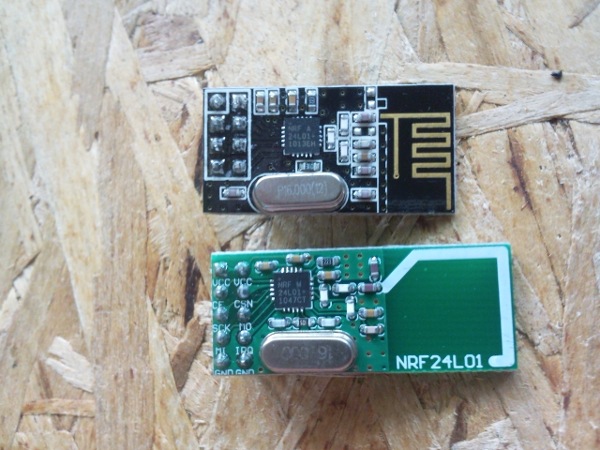

- nRF24L01 modules

There are two designs for this module: an 8 pin and a 10 pin. My board

is designed for the 8 pin version. But I had a hard time getting it to work;

it turns out that the module is sensitive to glitches on the rails, and my

board wasn't well designed to feed power to the module. A 10uF cap across

the rails at the module fixed it.

I was accidentally sent 20 modules of the 10 pin variety. Fortunately, 7

of the 8 pins line up, so the mod was trivial to get the 10 pin versions to fit.

This module is not as sensitive to glitches on the rail; I assume

there is on-module filtering.

- Servo motors

I ordered the 9g motors that are designed for model helicopters. Of course,

the samples I got consumed 3mA when idle and 60 mA when active. But the

production quantity consumed 6mA when idle, and peaks of 300mA when active.

This forced me to add a LiPo battery as a mod, in order to supply enough

current to the motor. In hindsight, I should have dropped the motor from the project.

- Accelerometer

I'm using the MMA8453. Be warned that this chip does not neccessarily power

up in a clean state; you must perform a software reset before using it.